Fast DTF Transfers revolutionize apparel design with precise, high-quality printing on various fabrics, from light cotton to thicker materials. Key factors include fabric selection, creative concepts tailored to target audiences and intended use, and efficient production workflows for competitive edge. DTF heat transfer paper streamlines processes, enabling swift customization and personalized products while minimizing waste.

“Revolutionize your apparel production with Fast DTF Transfers—a game-changer in modern manufacturing. This technology offers a swift, precise method for adding intricate designs to various fabrics. In this article, we’ll guide you through mastering Fast DTF transfers, from comprehending their fundamentals to selecting the ideal materials and streamlining production processes. Discover how this innovative approach can enhance your apparel design and boost efficiency.”

- Understanding Fast DTF Transfers for Apparel

- Choosing the Right Materials and Designs

- Implementing Efficient Production Workflows

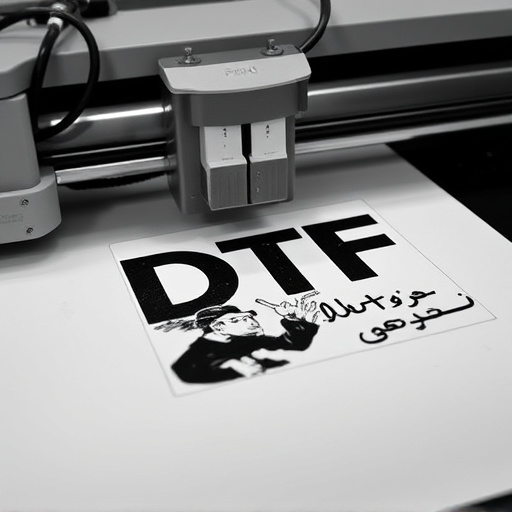

Understanding Fast DTF Transfers for Apparel

Fast DTF (Direct-to-Fabric) Transfers have revolutionized apparel design and production. This cutting-edge technology allows for precise, high-quality printing directly onto fabrics, making it an attractive option for businesses aiming to create unique, custom designs quickly. Fast DTF Transfers are especially versatile when working with a variety of light fabric types, enabling intricate details and vibrant colors to be reproduced accurately.

For darker fabrics, while the process may vary slightly, DTF printing remains a powerful tool. It offers designers the ability to achieve detailed graphics and text on even the most robust materials. The fast turnaround time of DTF transfers ensures that apparel manufacturers can meet demand promptly, making it an efficient choice for both small-scale custom orders and large-batch production runs.

Choosing the Right Materials and Designs

When using Fast DTF Transfers for apparel, selecting the right materials and designs is paramount to achieving exceptional results. Start by understanding the properties of various fabrics; not all textiles are suitable for DTF printing. Light, breathable fabrics like cotton and linen offer a smoother surface for precise detail transfer, while slightly thicker materials such as polyester or denim can accommodate more robust designs without smudging or skipping ink.

Consider your target audience and the intended use of the apparel when choosing designs. For casual wear, simple graphics and text work best, while athletic attire may benefit from bolder, sweat-resistant prints suitable for active lifestyles. Remember, Fast DTF Transfers offer unmatched versatility, so feel free to experiment with various colors, patterns, and creative elements to make your garments stand out.

Implementing Efficient Production Workflows

Implementing efficient production workflows is key to staying competitive in the apparel industry. Fast DTF Transfers offer a streamlined solution by reducing turnaround times and minimizing waste. By adopting direct-to-film (DTF) printing techniques, manufacturers can automate the process of creating custom designs on fabric with precision and speed. This technology enables on-demand production, allowing businesses to cater to diverse customer preferences without overloading resources.

With DTF heat transfer paper as the medium, brands can achieve high-quality results while maintaining cost-effectiveness. A direct to film printer becomes a versatile tool, capable of producing intricate patterns and detailed graphics directly onto the fabric. This innovation eliminates the need for complex setup processes, making it easier for apparel makers to adapt to market trends and personalize products according to individual needs.

Fast DTF Transfers are transforming apparel production by offering swift, efficient, and cost-effective solutions. By understanding the process, selecting suitable materials and designs, and optimizing workflows, businesses can harness the power of Fast DTF Transfers to meet demand promptly and maintain high-quality standards. This innovative technology is a game-changer for the industry, enabling quick turnaround times without compromising on intricate details or unique artistic expressions.